Deb Page and her husband Jim have written their own playbook for success, and it looks a lot different than most. The husband/wife team balances work, family and philanthropy with a flair that’s uncommon in modern American society.

About seven years ago, Deb, after learning the ropes of the mechanical trade from Jim, decided to open a full service plumbing, heating and AC company in Manchester, NJ. Jim’s 29 years in the trade gave him the ability to teach Deb what she needed to know.

Today, both husband and wife hold master HVAC licenses, and their oldest son, Sean, is in the process of learning as he works. While some married couples couldn’t imagine remaining happy while working with their spouse, Deb and Jim insist that they love working together, and it makes each day a family adventure.

The name Antigua Mechanical, LLC is borrowed from a city in Guatemala, and means “Land of Eternal Spring.” It is a fitting name for an HVAC company. It’s even more fitting considering that the couple spends most of their vacation time volunteering in Guatemala. When they are not working, spending time with their children, or volunteering, they are raising money or collecting tools to donate to charitable organizations in Central America and locally, in New Jersey.

*Click here to learn more about Antigua Mechanical’s philanthropy efforts.

That philanthropic attitude is one they’ve adopted in both their personal and work lives. It goes so far as to affect how they gain new customers.

“A great deal of our customers come to us because we’ll fix what other companies won’t,” explained Deb. “For example, a homeowner may call us and explain that their heat pump needs to be repaired and that other companies they’ve contacted refuse to fix it, only offering to replace it. If at all possible, we’ll make repairs to extend the unit’s service life another year or two, but only after being very clear that it’s a Band-Aid fix and the need for replacement is around the corner.”

Jim says, after helping a customer this way, they almost always hire Antigua Mechanical for the replacement job when the time comes.

Plumb and square

Fixing old equipment wouldn’t be enough to sustain a company, though, and Antigua is always busy. Jim and Deb seek to build sincere relationships with their customers, many of which become lifelong friends. They chat over coffee, deliver home-grown vegetables, and generally take an interest in the people in their community. But when it comes time to work, things get serious.

“I’m not a salesman,” said Jim. “We want our professionalism, attention to detail, and insistence on quality to speak for themselves. And we top it off with two years of free service on new installations.”

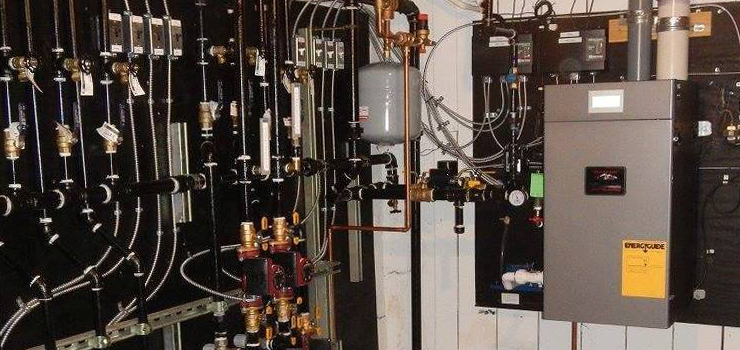

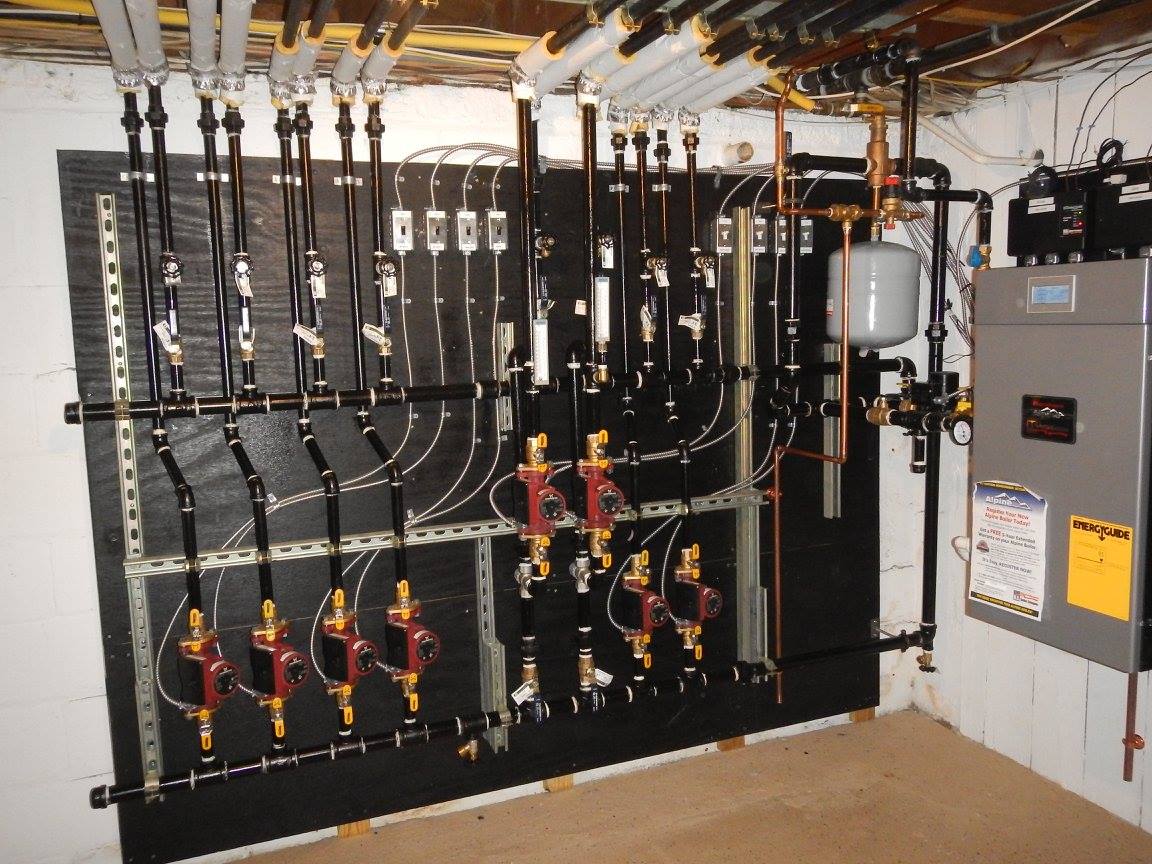

“If you take a look at one of our boiler installs, you’ll find that every pipe is level and plumb, wires are organized and only top-shelf components are used,” said Deb. “All the circulators have isolation flanges, and everything is supported with Unistrut.”

The company installs about 10 boilers each year, mostly between September and October. The majority of those units are Alpine high efficiency condensing boilers.

Most jobs come to Deb and Jim through referral, and most of those eventually lead to new referrals, for good reason. Not long ago, Antigua Mechanical completed a retrofit that yielded a $320 per month gas savings!

“When we went to the home in Red Bank, NJ, we found an old, 325 MBH sectional boiler and a stand-alone, 75-gallon gas-fired water heater,” said Deb. “The owner asked what our recommendation was, and we suggested installing a condensing boiler along with an indirect water heater.”

The boiler had an eight-inch steel stack, which shared a chimney with the existing water heater. After a load calculation, it was obvious that the boiler was grossly oversized for the home.

“The trip to the property was a no-heat call,” she explained. “The boiler was fouling horribly, so we fixed it at 7:00 PM and returned the next day to give the owner a replacement quote. At the time, she was paying about $500 per month for gas.”

Fixing radiant

The home was roughly 6,000 square feet and built in the ‘50s. It had numerous additions that were well insulated, and with good windows. The home had seven zones and a mix of in-floor radiant, baseboard and kick-plate that made up the distribution. Unfortunately, it was not all functional.

“The radiant zones were so hot that the homeowner knew not to use them, so certain areas of the home were not heated well,” explained Deb. “There was not any kind of mixing for the in-floor, so that was a priority on the new installation. We wanted 120°F supply water at outdoor design temperature. We really like installing in-floor heat because of the comfort and efficiency it provides, and it’s an area in which we’d like to expand in the future.”

Above: Deb and Jim like in-floor radiant work, and hope that this is an area of growth for them in the future.

The new piping layout, which was all done in black iron and mounted on plywood, mixes the radiant supply off the return piping. Ultimately, two zones were added; one zone was split because it exceeded the head limit on the circulator, and a 50-gallon Alliance SL was installed for domestic hot water.

Antigua Mechanical installs the Alpine high efficiency condensing boiler as often as possible. When budget is a consideration, they install the K2 condensing boiler, which shares the same great features, like the Sage Zone Control capability and broad size range.

“With the Alpine, we’re able to plug each zone into the Sage Zone Control panels for individual temperature control,” said Jim. “Because they’re expandable, we have two Sage panels on this job, while the 9th zone for DHW is high-temp and doesn’t respond to outdoor reset. Just like the Alpine, the panels are easy to install and easy to use. Deb does all the piping and wiring herself. It’s her favorite part of the job because she feels like she’s putting together a puzzle.”

No downtime

“The load called for a 180 MBH, and we ordered an Alpine to match,” said Jim. “During the summer, this would have been a pretty simple job. But since this job took place in late November, we needed to keep the heat on for the duration of the project.”

Above: The new Alpine boiler retrofit is saving the homeowner about $320 per month during the heating season. Antigua Mechanical also installed all new near-boiler piping and added two zones.

Luckily, the basement of the home was large enough for both boilers to share the space temporarily. The existing boiler was on the right side of the basement, so the Alpine and the new hydronic panels were installed on the left. The new boiler was vented horizontally out the front of the home. It terminates five or six feet behind a large bush, so it can’t be seen from the street.

Once the Alpine was running, Deb individually disconnected each zone from the old boiler and tied them in to the new supply and return piping. They completed three or four zones per day, and DHW was saved for last.

“This was the time consuming part,” said Jim. “Had we been able to tear out and install, we’d have been in and out in two or three days. But when we were done, the Bacharach said the boiler was running at 98% efficiency!”

Above: Deb’s favorite part of a job is piping and wiring.

The work continues

“The following month, we learned that the owner’s gas bill was $180,” said Deb. “On top of that, she had in-floor radiant that finally worked, and she mentioned that she no longer heard the boiler running in the basement.”

In the spring, Antigua Mechanical was called back to work on the home’s AC system. They added some new returns and improved other sections of the ductwork. The owner loves both systems.

“We’re just a little company,” said Deb. “We have no choice but to do it right the first time. But because it’s just Jim and I, we can take the time and do it the way it should be done.”