by Tom Secondino

Based on the response generated by our article on the USB-Connect and the influx of questions we’ve received, we felt it appropriate to provide a deeper look into the connected service tool. This month we will look at USB-Connect from a technician’s perspective. Let’s lead off with set up.

First, download the app for your respective phone. (Apple/IOS-Go to the App Store and download USB-Connect or Android-Go to the Play Store and download USB-Connect).

Open the app and create a user account. The company name must be selected from the drop-down list. If your company name is not listed, enter company information and then select your company from the drop-down list. Complete the registration and the app will open. Next, close the app out completely.

[wpdatatable id=41]

Once power is applied the LED on the tool will flash, indicating the tool is connecting to the boiler. When the LED turns solid green, you are ready to open the app on your phone. The app will initialize and look for the service tool adaptor. Be sure your Bluetooth is turned on in the settings menu of your phone. Once connected you should see the home page for the app.

Finally, for advanced systems with multiple boilers using the Sage onboard staging control, use the connection method shown in the photo above and diagram below. Note the interface is installed in the LEFT side of the display plug to link to the Modbus connections. Use an RJ45 coupler and cable 3 which extends the cable length to allow connection to the Envirocom port. Be sure to unplug the connector at the display while using the adaptor in multiple boiler applications.

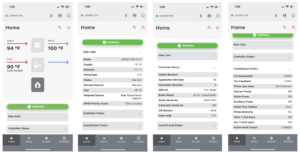

The images above display all the info available at the press of a button from the home screen. Just above the bottom tool bar are the main data, controller status, and I/O status buttons. Pressing one of these buttons will open a data screen. Available info for each screen is shown in the images above. Note the attention given to advanced diagnostic data by including fan command, fan resp onse, and flame signal in one location. (I/O Status page)

The screenshots above display some advanced features helpful during start up or diagnostics. The MENU button on the lower toolbar opens multiple options, one of which is the start-up wizard. Start-up wizard includes specific tutorials along with images for reference. Another feature found in the start-up wizard parameters would be EMS settings. All U.S. Boiler mod/con boilers can be cascaded allowing up to 8 networked boilers. EMS settings allow sequencer/ follower set up, as well as providing parameters to communicate with a building management system.

The Adjust button provides options that allow the technician to rate limit the boiler. There are separate inputs for the CH1 and AUX/CH2/DHW input, thus allowing independent and adjustable firing rate limits. The tool allows the technician to adjust gas valve and blower ignition settings to accommodate site specific variables. Keep in mind, with adaptive combustion the boiler will “learn” the dynamics of the installation and will auto-adjust accordingly! Should you choose to have an EMS or third party control dictate boiler modulation, the adjust menu allows technicians to select the input type (4-20/0-10) and scale the corresponding boiler temperatures as desired. Firing rate modulation is also supported, however in most cases setpoint modulation is preferrable and recommended.

The Adjust button provides options that allow the technician to rate limit the boiler. There are separate inputs for the CH1 and AUX/CH2/DHW input, thus allowing independent and adjustable firing rate limits. The tool allows the technician to adjust gas valve and blower ignition settings to accommodate site specific variables. Keep in mind, with adaptive combustion the boiler will “learn” the dynamics of the installation and will auto-adjust accordingly! Should you choose to have an EMS or third party control dictate boiler modulation, the adjust menu allows technicians to select the input type (4-20/0-10) and scale the corresponding boiler temperatures as desired. Firing rate modulation is also supported, however in most cases setpoint modulation is preferrable and recommended.

There are many other functions USB-Connect provides which due to space limitations unfortunately cannot be covered in one article. In the coming months we will be providing a series of short webinars featuring a live presentation of the USB-Connect service tool. Our goal is to provide an opportunity for those who have already come onboard to better utilize next gen diagnostic tools, and for the standing pilot die-hards to see first-hand that technology can be our friend! Winter is around the corner, and we are beginning to hear from some of our regulars again as the weather changes. During a recent call on the tech line, the caller expressed something we can all relate to, and we both had a good laugh. After helping him resolve a particularly challenging grounding issue, he shared the following; “You guys are like the perfect in-laws. Always there when I need you, never around when I don’t!”

In closing, I wish you all a safe, healthy and manageable start to the heating season. A wise man once said the only constant is change. Sometimes, though, we find comfort in safe harbors. As we’ve done for over 50 years, we’ll be here when you need us-and not hanging around your kitchen when you don’t!

* * *