By Mike Lee, Regional Director for Steve Lee & Associates

Ahhh, AC season. Time to think Indoor Air Quality (IAQ). But depending where you live, allergies are not the only airborne irritants, nor is late spring and summer the only time that brings these woes.

2017 was the year the West burned. Heavy snowpack and a damp spring across the West yielded thick grass and underbrush growth. What followed was one of the hottest summers on record, turning the lush greenery into crisp tinder. It was a layup for September’s lightening-riddled storm season.

By mid-month, there wasn’t a state west of the Mississippi that didn’t have multiple wildfires. Smoke haze from the Rockies could be seen for well over a thousand miles. In some areas, the Air Quality Index approached 200, or “very unhealthy.”

Simultaneously, Mother Nature ravaged coastal Texas, then Florida. Days of rain and the ensuing floods brought by Irma and Harvey stand in stark contrast to the wildfires that charred the mountain states, but there’s definitely one correlation. Both natural disasters present severe air quality challenges.

While fires present an immediate air pollutant danger, the residual bonfire scent within nearby houses is also a reality. And where hurricanes flooded homes, indoor mold growth is almost guaranteed if moisture isn’t dealt with swiftly and properly.

Modern IAQ: The challenge, the business

For most homeowners across the country, these may seem like isolated issues. But regardless of location, IAQ has recently gained major awareness, and it’s a profitable business for the contractors who offer it. The weather seems to grow more extreme every year, as do the allergies and breathing ailments we face. People spend more time indoors than ever before, and information on indoor air quality is widely available online. Information like the fact that indoor air is two- to five-times more polluted than outdoor air.

Quite possibly the biggest factor, though, is modern home construction. As part of the ongoing pursuit of efficiency, houses are being built tighter. Thanks to ASHRAE Standard 62.1, commercial buildings have makeup air requirements. Private residences do not. When extremely limited infiltration is the only form of makeup air, airborne toxins (mold, bacteria, viruses, fungi, VOCs, particulates, etc.), have nowhere to go.

Those who suffer from Asthma or allergies are generally the first to notice poor air quality. Other times, the problem is obvious to anyone in the building. A damp smell is indicative of moisture, and that’s often accompanied by mold. And dirty sock syndrome is a perplexing issue in hot, humid environments. In years past, retrofit IAQ options were largely limited to larger filters and UV lights. But the recent groundswell of interest has spurred the development of new air purification technology in recent years.

Many options

Ultraviolet light systems installed within an air handler have proven to be effective in many situations. When used alone, the upfront cost of a UV light is reasonable, and installation is relatively simple. Bulb replacement is a consideration, though.

UV lights only purify whatever the radiation comes in direct contact with. That is, the system has no effect on a shaded part of an AC coil, and has zero residual effect throughout the ductwork or home. UV lights also don’t aid in filtration, so allergy symptoms caused by inert particles aren’t affected.

But UV lights aren’t the only option. Corona discharge systems create positive and negative ions through the use of a glass tube and metal mesh. The ions destroy many airborne impurities without causing any harm to building occupants. But the voltage potential across glass bulb can allow ozone production. The tubes also have to be replaced every year or two.

Photocatalytic systems include a UV bulb, but rather than shining the light on the coil, the radiation is concentrated on a titanium screen-like element. This creates complex chemical ions, which destroy pathogens. Ozone sensitivity and bulb replacement is a consideration, though.

Ozonizers, yet another technology, are very good at decontaminating indoor spaces full of pathogens, but cannot be used in occupied areas because of the health risk that ozone creates. These systems are often used to decontaminate a room while unoccupied. Think – removing unwanted, lingering smells, like a home that has sustained smoke damage, or pet urine.

An alternative

One newer technology that avoids the use of UV lights altogether is Cold Plasma Generation (CPG). CPG systems, which have been available for about a decade, create an electric, or plasma field inside the ductwork. As air flows through the field, molecules are highly charged, creating natural positive and negative ions.

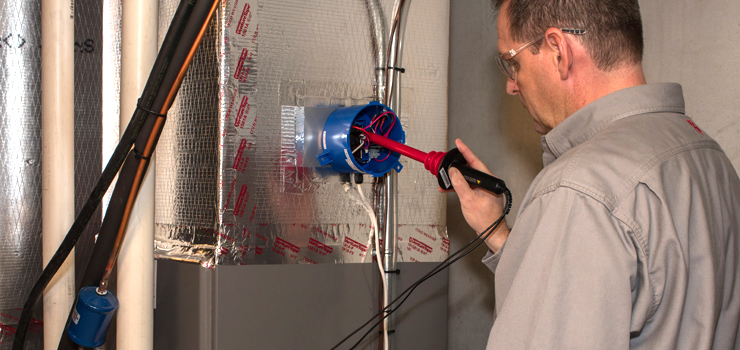

Above: The ideal location for a CPG system is in front of the evaporator coil, though the unit is effective behind the coil or even at supply air discharge.

While the plasma field is contained within the ductwork, the ions travel throughout the home with the airstream. The ions, constantly “looking” to become de-ionized, will either steal or add an electron to other particles they come in contact with. For example, a negatively charged ion will pull an electron from a mold spore, killing it. In this manner, CPG also kills viruses and bacteria.

Similarly, a CPG system will destroys scent molecules and VOCs. As these impurities pass through the plasma field, they’re broken down into simple molecules, such as hydrogen, nitrogen and oxygen.

Conventional particulate filtration is also increased because the charged ions draw microscopic particles together, growing until large enough to be captured by filter media.

Retrofit ready

Unlike UV and photocatalytic systems, very few manufacturers offer CPG systems. Phenomenal Air offers several different CPG ion generators. Rated for applications up to 6,000 CFM, the Series R unit fits most residential applications and installs very quickly. The low-voltage generator is about the size of a softball, with two CPG legs, or “anode brushes.”

The generator is mounted on the outside of the ductwork or air handler. The units should be installed downstream of filtration media.

Above: The generator is mounted on the outside of the ductwork or air handler, while the anode brushes protrude into the airstream.

No detectable ozone is created by any of Phenomenal Aire’s CPG systems, eliminating the health concerns that some IAQ systems pose. Installation and maintenance is fast and simple. There are no parts to replace, and the anode brushes should simply be wiped off during annual maintenance.

Integrating IAQ in your business

A wonderful thing about the IAQ business is that the bulk of the interest comes in the swing seasons, right before AC and heating seasons.

Many research reports show that 50 percent of the U.S. population have allergy issues. When half of your customers have an issue, doesn’t it make sense for you to have a solution? And just as important, if selling an IAQ system gets your foot in the door, that customer may very well hire you later for other services.

There are more IAQ options and technologies available now than ever before. It’s worth doing research before settling on a system that you’ll sell. I’ve spoken with contractors and homeowners who’ve had bad experience with IAQ, whether it’s been because of improper installation, the equipment simply fails to perform, or their bodies have reacted to a byproduct the IAQ technology (we’ve seen individuals with a sensitivity to ozone).

But to say the least, IAQ is not something to ignore. The mechanical firms that have learned to sell the systems effectively have benefitted. And as IAQ challenges evolve, the technology used to handle it must evolve as well.

Michael Lee is a Regional Director for Steve Lee & Associates, the HVAC/R division of Sunbelt Marketing. He manages the company’s HVAC Sales in the North Carolina South Carolina, Tennessee, Kentucky and Virginia.