By: Tom Soukup

By: Tom Soukup

I’ve been in this trade for 20 years. Much has changed in that time, but two things in particular are very different from when I lit my first standing pilot.

First, equipment has gone from “dumb” to “intelligent.” That includes boilers, controls, T-stats, tools and even utility vans. Second, society wants instant gratification. They want it now, and they want it perfect.

Both changes impact our profession, and neither is going to change. So we need to.

That means more preparation, thoughtful design, and precise execution. The days of “winging it” are long gone for our industry. Now, everything must be planned, calculated and accounted for.

I realized this a while ago and started making changes in the way my company operates. The big turning point, though – the “lightbulb” moment, as some would say – came when I first pre-fabricated a boiler system.

These days, 90% of the boiler systems that my company installs are pre-assembled in the shop after carefully measuring the spaces and taking lots of pictures of the area in which they need to fit. We’ve found that this creates a better end product, reduces our time onsite, cuts overall labor by 20%, and drastically curtails system downtime during the retrofit.

Room (and time) to work

Our prefab shop has plenty of space and light. Working on a table means we’re not stooping over or resting on our knees. Big equipment is already in place, so we’re not wasting time with set-up and tear-down. We have jigs and spacers for a variety of system types and sizes, depending largely on the number of boilers in a system (more on that later).

The shop offers a relaxed atmosphere; no customers watching, no other trades fighting over a single power outlet, no messes, no loud noises, etc. This all means greater attention to detail. Burn permits and fire watch are also a thing of the past. Hydronic racks are accessible from all sides, unlike working against a mechanical room wall.

We make our racks out of Unistrut and build the system up from there. If the system is meant to heat a pool, or will be exposed to a caustic environment, we use stainless steel rack material. We are also exploring the possibility of using NIRON PP-RTC pipe instead of copper in these systems.

Next, we preassemble the entire boiler system. This includes completing all the wiring and components. Everything is assembled loose and will be press connected later in the field. Once the system is complete, we take a picture, label everything with tape, break it down, put it in a box, and reassemble it onsite like a simple jigsaw puzzle.

Cost, redundancy, turndown

Prefabbing boiler systems makes my company more competitive and provides a better product. Plain and simple, it just makes the job easier.

Through the process of developing our pre-fab methods, we found another trick to adding value on our commercial and multi-family installations. Prefabricating boiler systems makes it easy to install multiple condensing boilers. We’ve found that it’s less expensive, per BTU, to install multiple small boilers than a single big one.

For example, a lot of the systems we replace require about 450 to 550 MBH. In those situations, we fabricate hydronic systems with three U.S. Boiler Company K2 condensing boilers. If we need less firepower, we can drop to a smaller model. Need more heat? Add boilers!

Like I said, equipment cost per BTU is slightly less with multiple boilers, but there are a lot of other huge advantages. There’s redundancy with multiple boilers. The units are physically easier to handle. Turndown ratio goes way up. In the case of the K2 boilers, three boilers provide a full 30:1 turndown. Pair that with 95% AFUE, and we’re talking about some major energy efficiency.

All that turndown also means that we can be more flexible in our boiler sizing. Properly staging the units through the K2’s Sage controls means that those boilers will be running long hours at minimal input. That’s the perfect recipe for low fuel use and long boiler lifecycle.

Multiple boiler installations are great for all the reasons I just mentioned. However, they can become a major headache and piping mess in the mechanical room without a solid design and the ability to prefab system components.

Customer satisfaction

Forget about cost. Forget about efficiency. Just focus on the customer experience provided by a company that prefabs their boiler systems. It’s here you’ll find the biggest selling point for most commercial facilities where time is of the essence and managers are extremely busy.

We were hired to replace the boiler system at a retirement facility recently. We constructed the entire system in our shop weeks before demolition day.

On day one of the actual install, we had the old system torn apart, all of our racking installed, and piping started. Day two had the boilers in place and fired. Day three included the finishing touches, control details, and customer orientation. That can only be done with prefabrication.

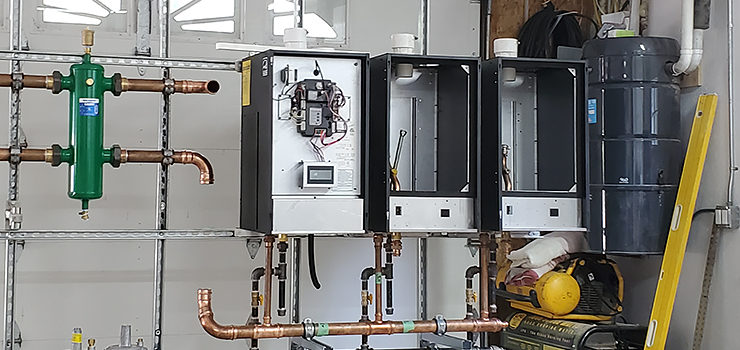

Above: A K2 boiler installation on-site after being prefabricated.

Beyond speed, prefabbing commercial boiler systems has other advantages. Building the system before the project starts eliminates any change orders. Also, we take full accountability of the system, eliminating the footwork and orchestration needed on the customer’s part. They do not need to be concerned about an electrician, a plumber, and a gas tech in addition to us. We provide one point of connection for each of these trades.

Tom Soukup is the principal of Patriot Water Heater Co. with over 20 years as a hydronic designer and installer. He specializes in high-efficiency and green technology and brings his expertise to custom commercial work, pool heating, and agricultural projects. Reach him at: twsoukup@patriotwaterheater.com