When Temple Baptist Church, located in Pueblo, CO, needed to replace their oversized, antiquated boilers, they called Moose Plumbing & Heating.

Jason Mulso – whose friends call him “Moose” – started the company in 2005. He and his two employees serve southern Colorado. Residential work is the focus, but they do enough commercial work to keep it interesting. Churches, car dealerships, and the occasional large home break up the steady flow of 100 MBH boiler installs.

“It’s a big church,” said Moose. “But at roughly 13,000 square feet, it’s not 1.8 Million BTUs big, which is what they had installed when we arrived. A heat load calculation called for around 1 million.”

In addition to wrestling the big old units out of the building, they also had to design a distribution system that could handle some level of hydronic fluid impurities while accommodating the extensive zone valves scattered around the building. Because efficiency was a key concern, his plan was to use a dual, modulating boiler approach and variable-speed circulation.

Less is more

Once they’d gotten approval to start, the Moose crew pulled out the existing boilers and installed two new, stainless steel U.S. Boiler Alpine Commercial boilers. The new, smaller condensing units are daisy-chained together to fire in lead-lag configuration.

“The Alpines at the church rarely – if ever – both reach high-fire simultaneously,” said Moose. “We use the Alpine a lot on residential work, so it’s fun to install the commercial model when we get a chance. They are easy to install, just like the wall-hung models.”

The U.S. Boiler Alpine line offers capacities from 80 to 800 MBH and the commercial models boasts thermal efficiencies up to 97%.

Above: Jason “Moose” Mulso, founder of Moose Plumbing & Heating in Cañon City, CO, links the two Alpine Commercial boilers together.

In addition to heating the structure, the common primary boiler loop feeds two, 60-gallon indirect water heaters. One tank provides domestic hot water to the entire building, while the other is dedicated to a small baptismal pool at the front of the sanctuary.

Pumping smarter

The original church was built in the early 1900s. A number of additions spanning the decades made the hydronic system a bit more complex. An assorted mix of convectors, fan coils, fin-tube and cast iron radiation is used.

The saving grace however, was that each zone is controlled by a remote zone valve, all of which are operational. The system was divided into two sections – or secondary loops, so to speak. The nursery and sanctuary make up one of the sections, while school rooms, a cafeteria and gymnasium are on the other.

“I worked with a rep at McCoy Sales to select the right circulators for the two areas of the church,” said Moose. “The load varies greatly depending on the activities going on in the building. So we needed a high-head, high-flow pump with the ability to vary its speed considerably, and do so without a control system or remote pressure sensors.”

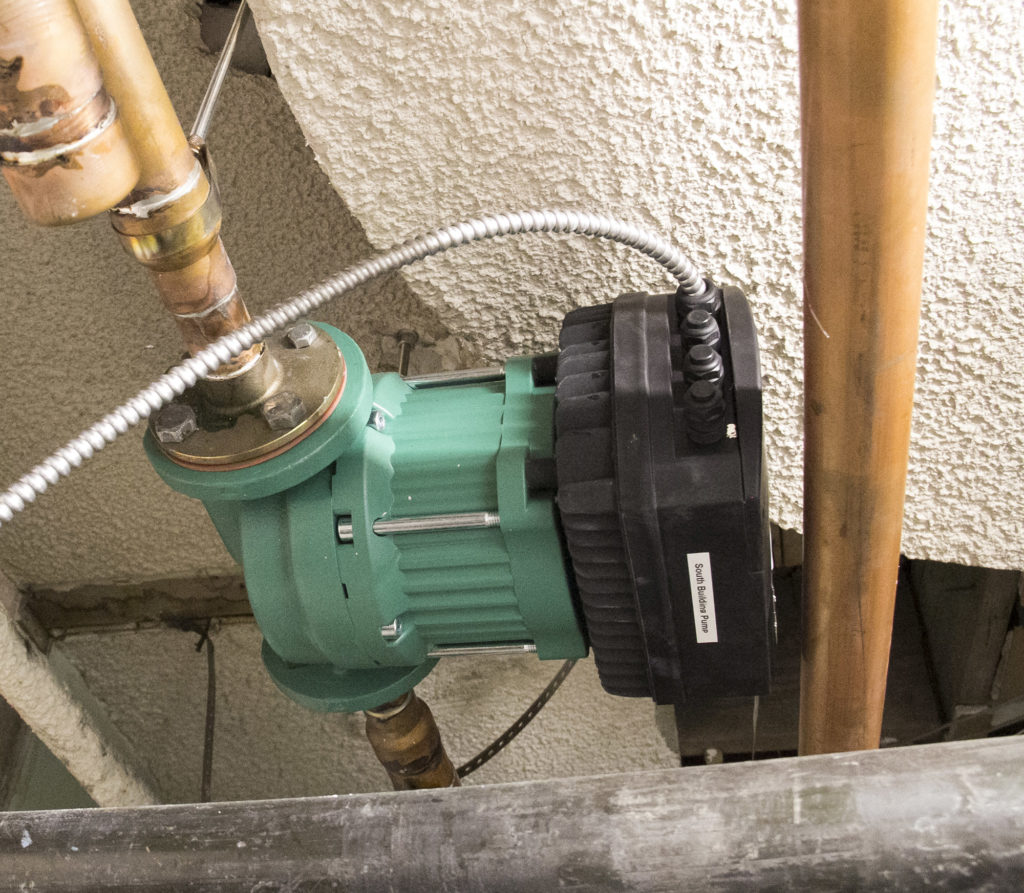

McCoy suggested a large ECM circulator with an internal pressure sensor. It now ramps up and down as needed to match the pump curve to the system curve at all times. With the use of an ECM circulator, Moose is also providing the congregation with electric savings compared to a conventional circulators of similar capacity.

Above: A variable-speed Taco 00e Series VR30 circulator is used on each of the big secondary loops.

“This is the biggest circulator we’ve installed in quite a while, but even if just one zone is calling, the pump is providing the correct flow rate,” he explained. “And there are no more banging zone valves as a result of an over-pumped system.”

Heavenly improvements

Moose P&Hworked off and on for three weeks to complete the job. Each day began with a 40 mile commute from their shop in Cañon City. But the result of their hard work was beyond what the church had hoped for.

Above: The finished installation of two, 500 MBH Alpine Commercial boilers by Moose Plumbing & Heating. The retrofit saved Temple Baptist Church a significant amount in gas savings.

“Fuel consumption over the first three months was down by 35 – 40%,” said Moose. “But, before they even saw the gas savings, they felt a big change at the front of the church.”

The baptismal pool was far more comfortable than they’d ever experienced. It turns out, when you remove an old, 40-gallon gas-fired water heater and replace it with 1 million BTUs of boiler capacity and a sidearm tank, you can generate hot water a little more quickly!