By Jason Ridgeway

We installed our first hydronic snowmelt system in 1995. It’s not a huge part of our business, but the projects are typically large, and we do half a dozen or so per year in the greater Chicago area. The largest we’ve installed is 55,000 square feet.

Six per year doesn’t sound like a lot, but they’re pretty involved and can fit nicely into the shoulder seasons if there’s flexibility in the customer’s timeline. We also don’t advertise the service. All our leads come word of mouth, and there’s generally a trend; When one person in a neighborhood invests in snowmelt, others in the neighborhood tend to follow suite.

We’ve found that the folks most likely to install a snowmelt system are those with (or soon to install) a paver driveway, or those with steeply sloped driveways, which are obviously a hazard when covered in ice. With that said, snowmelt is really all about appearances. That’s what we’ve learned, anyhow.

Paver driveways are good applications for two reasons. First, if the driveway is existing, the pavers can be lifted and reset after the snowmelt system goes in. Second, pavers are easily damaged or shifted by plows or snow blowers. Snowmelt removes these concerns completely.

Top tips

Before I dive into the technical aspects of designing and installing a snowmelt system, here are my top three tips:

1. Only work with experienced subcontractors:

The concrete/paver subcontractor must understand what you’re doing and help protect the tubing during their portion of the work. I’ve seen stakes driven through tubing on multiple occasions, so working with a quality paving sub is paramount.

Discuss with your customer if they have a driveway contractor in mind. We tell driveway subs that once we have the system pressurized to 100 PSI, it becomes their baby. If something happens to the tubing, it’s on them. Also, if the time between our tubing installation and the driveway finishing is to be more than a few days, the tubing must be meticulously covered by sand or tarps to protect it from UV damage.

Speak with that sub to gage their familiarity with snowmelt, and don’t be bashful about suggesting a contractor you’ve worked with in the past if you see any red flags. You’ll thank yourself later.

2. Pick your boiler correctly:

It goes without saying that you should use a boiler you’re very familiar with, especially because you’ll be asking it to do something a little out of the ordinary. Beyond that, it’s just as critical to size the boiler correctly for snowmelt as it is for space heating. All the same rules apply. Short cycling is just as big an issue no matter the application, and many of the snowmelt systems I’ve looked at are oversized.

3. Try to Add Value:

Snowmelt is a luxury, and the price tag reflects that. I’ve successfully overcome resistance on pricing by adding value to the installation. For example, instead of committing the boiler entirely to the driveway, find other ways to use heat. We’ve added indirect water heaters and garage unit heaters in the past. Maybe they’re planning an addition on the home at the same time. Can this be heated by the snowmelt boiler? Provide something that customer may like to have, but would not be likely to install a dedicated boiler to handle.

What’s under the driveway?

The beauty of a snowmelt system is that the customer never sees or hears their snow being removed, and there are no chemicals being applied, which can damage lawns, landscaping, and the driving surface (not to mention the environment). However, the fact that it’s invisible makes what’s beneath the surface that much more important.

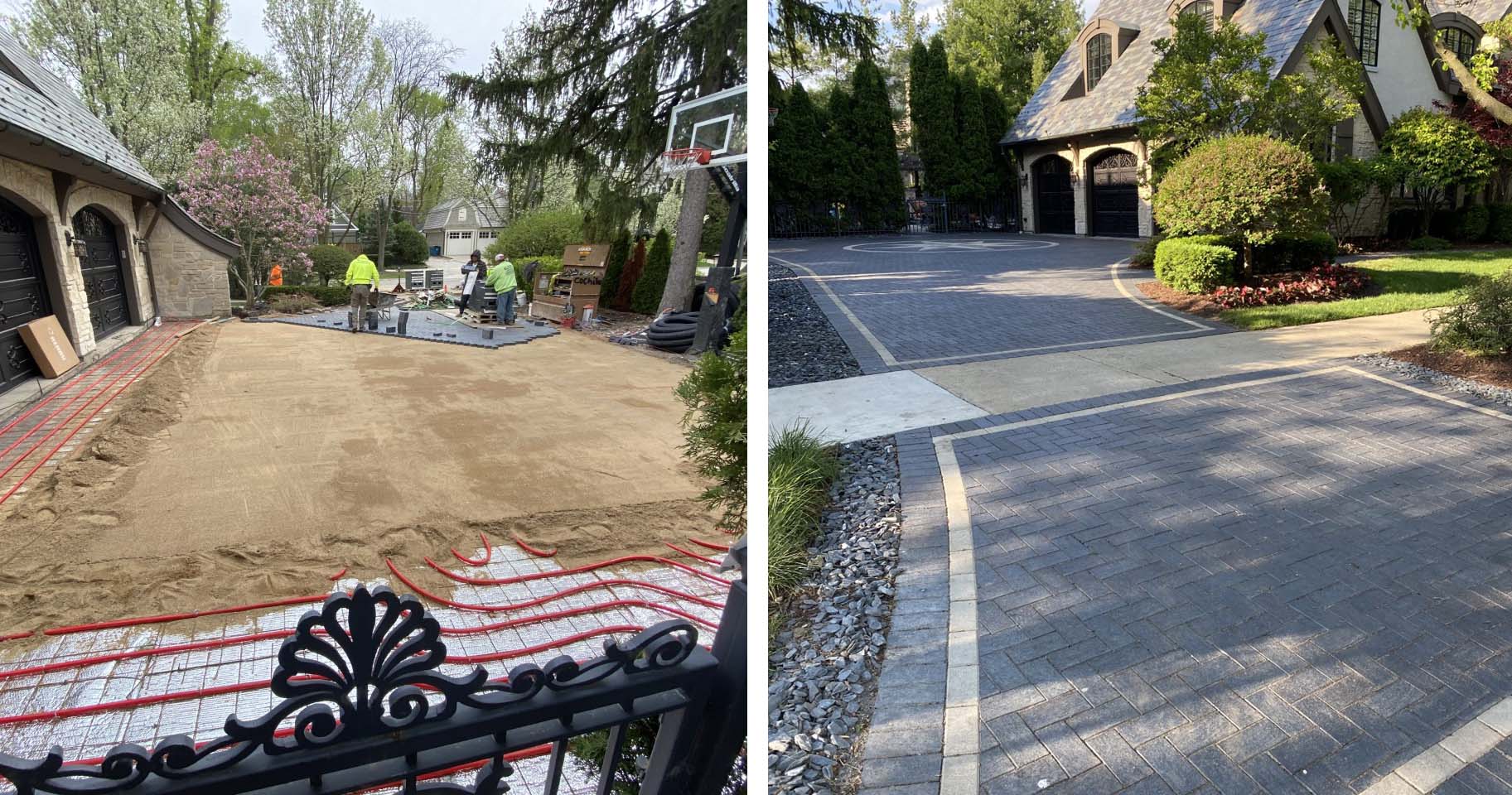

A properly designed snowmelt system starts with excavation. The driveway excavation must be deep enough to permit the tubing installation and everything that goes along with it. This starts with a sub-base layer of stone, which provides a solid base and good drainage. On top of the sub-base, we install a ¼-inch, R-9 reflective bubble wrap product that we perforate to permit drainage. Over the insulation, we lay wire grid, to which the hydronic snowmelt tubing is attached. If the driveway is to be surfaced with pavers, a two-inch layer of sand (base) is added before the pavers are laid. It’s critical to use enough sand. Too little sand will result in shifting pavers and possibly damage to the tubing. If the driveway will be concrete, it is poured directly over the oxygen-barrier hydronic tubing in lieu of sand.

It’s worth mentioning that snowmelt systems can’t be installed beneath asphalt surfaces. Most mechanical contractors already know this, but it may come as a surprise to customers.

Components

Selecting the components for a snowmelt system is just as important as for a high-end residential heating application, maybe more so. You’ll need to be well acquainted with the boiler. We’ve been asked if we can install conventional boilers instead of condensing boilers. Cast iron boilers can be used, but heat exchangers must be installed to protect conventional heat boilers.

We don’t use outdoor reset. Our supply water temperature is 160°F degrees – which yields a surface temperature – at least in our area and with our insulation – of 35°F or 40°F. It’s extremely important not to overheat the slab. Doing so can damage the driving surface.

The manifolds used should be of vertical configuration if possible, and they should feature balancing ports. This helps with air elimination and offers a little bit of flexibility in loop length. Speaking of manifolds, we try our very best to avoid using remote (yard) manifolds. These are hard to work on and just create opportunity for a landscaper or lawn mower to damage the customer’s investment.

It goes without saying that the system needs to be protected from freezing. We run a 50/50 propylene glycol mix, which provides freeze protection down to -15°F. As such, boiler makeup water can’t come from a well or city supply. Instead, use a large system feeder with the correct glycol mix. It’s important to monitor glycol levels and the glycol pH.

Control

There are two primary ways to provide control on a snowmelt system. Either manually or automatically. A manual system simply has an on-off switch, which the customer can flip in the event of snow on the forecast, but we don’t suggest that. If a manual system is installed, some homeowners will allow a system to “idle” all winter. This will consume more energy than using an automatic system.

The alternative is an automatic system, which features a slab sensor. This device reads the surface temperature and senses moisture. When there’s moisture and the temperature is low enough, the system will come on. If the driveway is large enough to require zones, each zone will have a dedicated slab sensor. This is how we control all of our systems unless otherwise requested.

Design

The PEX we use is either 5/8-inch or 3/4-inch, depending on the length of our loops. For example, the maximum loop length for 3/4-inch is 300 feet. If there’s a walkway with much tighter bends needed in the loops, we’ll occasionally use 1/2-inch PEX.

I design the systems myself, using design software to determine the tubing count and flow rate based on resistance and BTU capacity of different pipe size. To help calculate the heat load, know that residential snowmelt systems need 100 BTU per square feet, at least in our area. Commercial systems need 150 BTU per square foot. That number jumps up quite a bit in “ambulatory” applications. These are critical areas where the surface not only has to be free of snow and ice, but must be dry. You’ll find this with helipads, hospital entrances, etc.

In a typical installation, our pipe spacing will be six to eight inches. Tighter in an ambulatory system.

Cost to operate

Typically, if the customer is willing to pay for the initial cost of a snowmelt system, they don’t balk at operating expenses. An average driveway for us is between 1,000 and 2,000 square feet. At current natural gas prices, melting that driveway will cost around $100 per snow event. Compare that with the cost of a quality snow removal contractor who is also applying ice melt chemicals, and there’s not a great deal of difference.

A driveway with snowmelt will look better in the winter, the driveway surfaces, landscaping and lawn will be protected, and the resale value of the home will be higher.

I know for a fact that our snowmelt customers love their systems, though. I’ve had them complain more loudly over a snowmelt system that didn’t fire because of a simple control issue than people who call with a no-heat complaint!

Jason Ridgeway is owner of Ridgeway Home Services, serving the greater Chicagoland area. The third generation company – going on its fourth generation – is an eight person firm that specializes in radiant, snowmelt and geothermal.