John Romano entered the trades the way most folks do. He began as an apprentice with a medium-sized mechanical company and learned as much as he could.

His boss was a great teacher and a boiler mastermind. After years of learning and doing, Romano became a licensed plumber and a very savvy hydronic technician in his own right. But things change, and so did Romano’s career.

Eventually he left the field to work for a technology manufacturer. What he didn’t expect was that he still had the itch to spin a wrench. With a flexible work schedule, he decided to found a small HVAC and plumbing company and continue practicing the craft part time. Today, five years later, he’s found a happy medium, working for himself while also continuing his day job.

John Romano Plumbing and Heating is a one-man operation in Derby, CT, but helpers are hired as needed. While Romano does everything from renovations to drain cleaning, he specializes in hydronic work. Much of it is high-end installations, like snowmelt and radiant.

Tell it like it is

“I charge more than most contractors in my area, but I don’t have trouble closing sales,” said Romano. “I think that’s entirely because of my approach. I’m honest, whether it’s what a customer wants to hear or not. I give honest opinion, I don’t overpromise, and I explain why I believe my solution is the best available. If they don’t like it, they can, and will, call someone else. No hard feelings.”

One of Romano’s opinions is that cast iron boilers are usually the best option.

“Let’s face it, homeowners don’t like maintenance,” he said. “On occasion, I’ll install an Alpine because

the controls are very flexible, but generally speaking, the MPO-IQ and MegaSteam are my go-to boilers.”

Oil was prevalent when Romano was an apprentice, and the folks he worked for knew oil as well as anyone in the country. The knowledge rubbed off, and today, more than 75 percent of the equipment Romano installs is oil-fired. The rural parts of his service area still don’t have access to natural gas.

“When I worked for someone else, I probably installed an MPO-IQ every single week of the year,” said Romano. “Now, on my own, it’s more like five per year. I can install the units, sleep well at night, and provide decent energy savings to customers, regardless of the home it’s installed in.”

Undersized and out of luck

One of Romano’s most recent MPO-IQ installations was at a 1930s Colonial in Milford, CT. The job came by word-of-mouth in December of 2017, and while they were happy to show Romano the existing system, they were very angry about their situation.

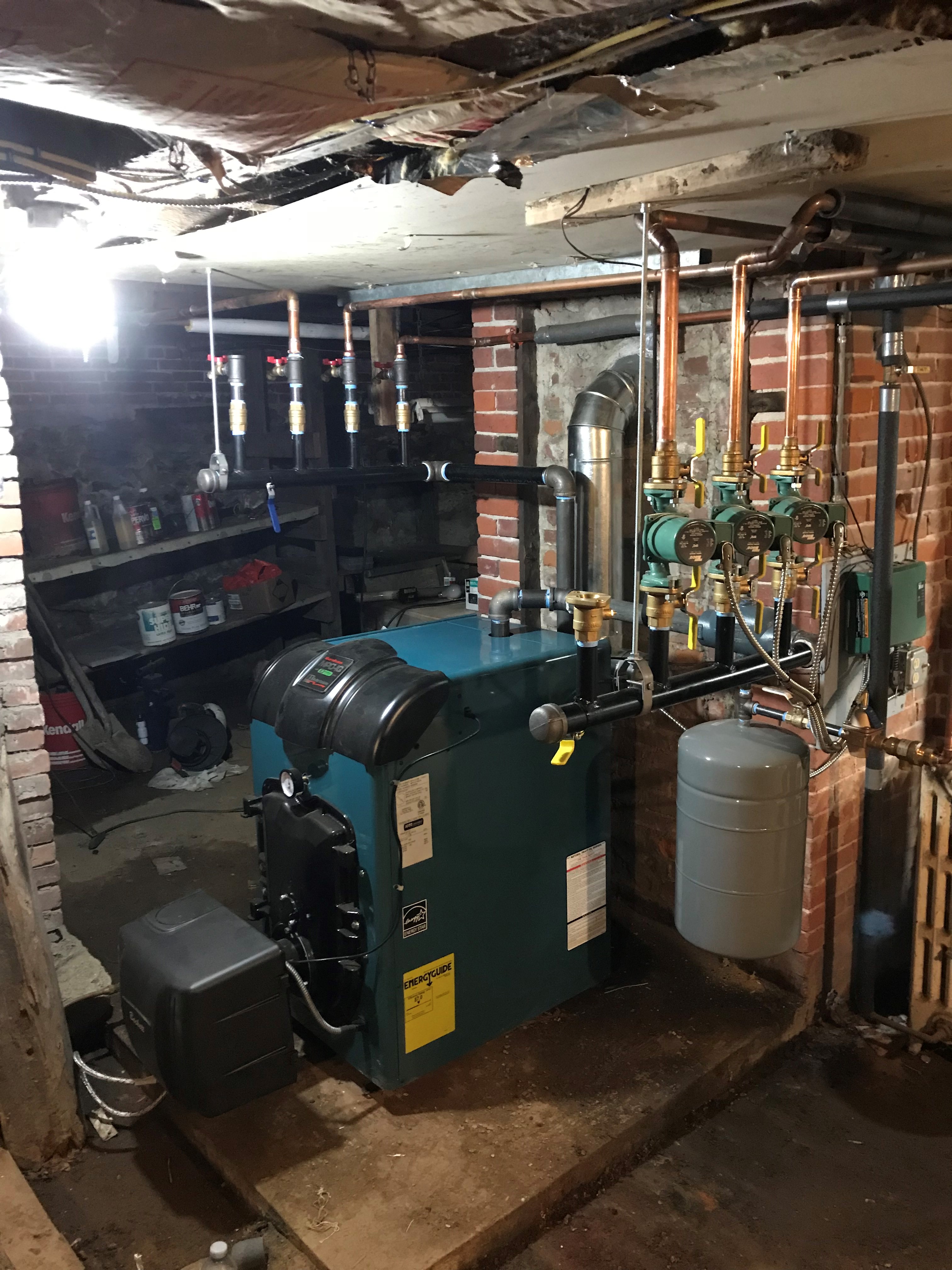

The existing unit was undersized for the 7,200 square-foot home. To make matters worse, the auto-feed valve had been installed wrong, and the boiler cracked as a result. The existing zones of U.S. Boiler Baseray cast iron baseboard hadn’t been laid out very well, either, and the loops simply were never balanced properly.

“I realize that time is money, and spending a whole lot of time onsite before getting the job is inefficient in the minds of some people,” said Romano. “But I start a notebook on every job during the first visit. I take notes on everything, not just the heat load. What good is expediting the visit if it’s going to cost me time and money later to fix something I overlooked, on top of having an unhappy customer?”

Above: Romano installs a MPO-IQ oil boiler in a 1930’s Colonial basement in Milford, Connecticut. The high efficiency oil boiler saved the homeowner $120 on oil in the first three months.

After learning that the heat was uneven throughout the home, he noticed that the main loops had butterfly valves on each branch. So he made a note to buy new balancing valves. His plan was branch off to each floor of the home with fresh ¾ inch copper.

Romano cleans each chimney before installing a new system. If a masonry chimney is deteriorating, as it was on this job, he suggests a contractor to line the flue. After conducting a heat load calculation, he settled on a 230 MBH MPO-IQ boiler for the big house.

Easy choice

“Without the option to switch to natural gas, the MPO-IQ was a no-brainer,” said Romano. “Aside from the three-pass design, which provides simple maintenance and better efficiency than most oil boilers provide, I like the MPO-IQ because I can sell it in stages, courtesy of the plug-and-play IQ cards. If the owners don’t want outdoor reset or a low-water cutoff, I can always offer that the following year when I visit the site for maintenance.”

On this particular job, Romano sold the outdoor reset right away. Considering the higher mass of the cast iron baseboard radiation, the advantage of slightly lower water temperatures in less than design conditions was multiplied.

“With cast iron radiation, I don’t need 180°F supply water,” said Romano. “Most of the year, this system will maintain 168°F to 172°F, with the ability to deliver 180°F at design conditions. Typically, that means a return temperature of about 150°F to 155°F.”

“I also resized the pumps,” said Romano. “I find that many people think pump curves are irrelevant. A system isn’t going to operate like it should with the wrong pump, especially in a house this size.”

Now the home has five zones with a 6th stubbed in for a future addition of an Alliance stone lined tank when the existing water heater needs to be replaced.

The homeowner saved $120 on oil in the first three months, meaning the potential to save more than $200 per year. Romano has done jobs where the savings are more than $500 per year.

“I don’t overpromise energy savings,” said Romano. “There are too many variables between the heating degree days each year and fuel price fluctuation. Also, I’ve found that if you tell some customers that they’ll be saving a bunch of money, there’s no guilt associated with turning up the thermostat, and they won’t see the fuel bill go down anyway. I’m honest about what I can deliver, and I let the results speak for themselves.