Hydronic chilled beam systems offer one of the best, most efficient means of heating and cooling interior commercial spaces. Currently, with broad concerns about improving indoor air quality (IAQ) in response to COVID-19, active chilled beams are enjoying a resurgence of interest among professionals in the commercial building industry.

Key advantages of hydronic chilled beams include their slim, in-ceiling installation, inherent efficiency (water provides the best means of transporting BTUs throughout an occupied space) and the fact that active chilled beams provide the ideal means of decoupling the sensible heating or cooling load from the building’s latent load. This is especially interesting now, as the industry is poised to demand greater fresh air provision to commercial buildings.

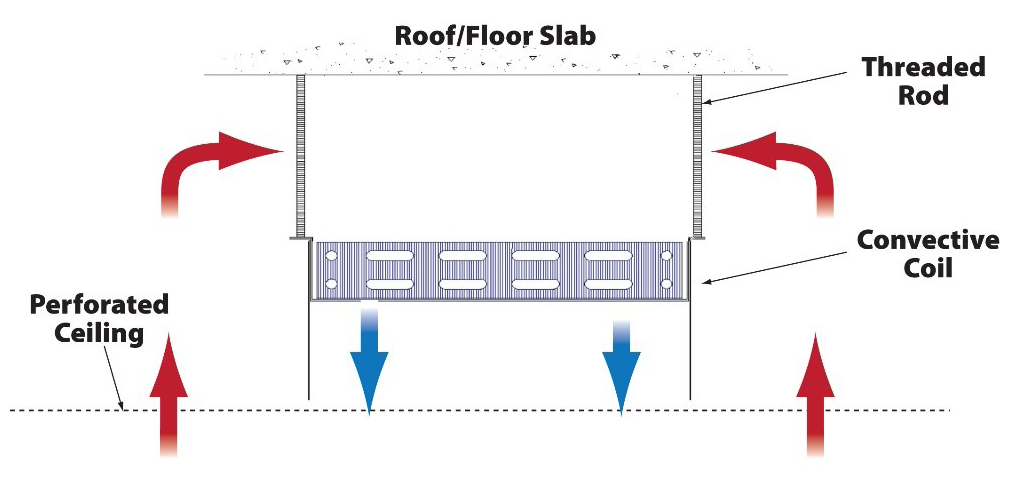

An active chilled beam is a part of a convection HVAC system. Pipes of water are passed through a “beam” (a hydronic coil) mounted within or just below the ceiling. These are sleek-looking, low temperature radiators most often used in offices, universities, hospitals and laboratories. See Figure 1.

Figure 1

Active Chilled Beam Systems

There are two types of chilled beam systems: active and passive. Active chilled beams are terminal hydronic units that include a small supply of outdoor air. Most of the chilled beams sold in the US are active, and active chilled beams, (unlike their passive counterparts) can be used to provide fresh air to a building.

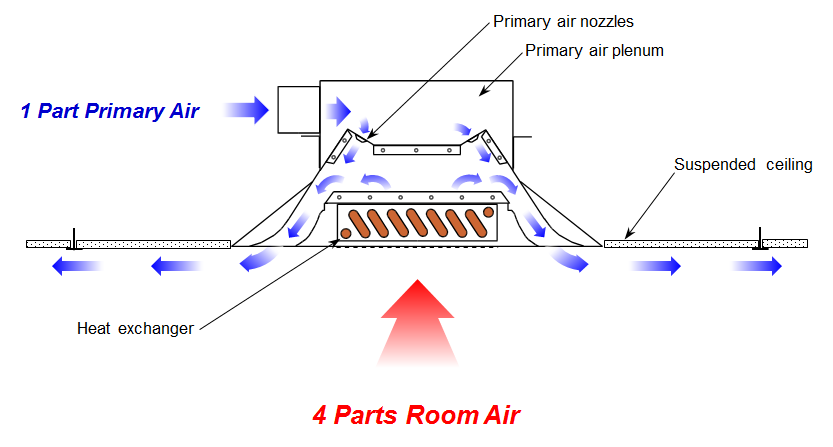

Fresh, outdoor air is supplied to the beam from a DOAS (dedicated outdoor air system) via small ductwork, entering the beam’s primary air plenum. From there, it’s passed through a set of high velocity nozzles, creating low pressure inside the beam’s mixing chamber. This low pressure draws air from the room up through the coil, where it’s mixed with fresh air and returned to the room. See Figure 2.

Figure 2

Active chilled beams either warm or cool air from the DOAS as the air passes through the unit’s coil, which receives cool water from a chiller system or warm water from a boiler. The goal is to provide air that is very close to the ambient room temperature. In a heating application, this means that the supply water temperature to the beam is generally between 90 and 140°F, perfect for a condensing boiler application.

In cooling applications, the chilled supply water temperature to the beam must be above dew point to prevent condensation from forming on the underside of the panels. This typically means chilled supply water in the range of 55 to 60ºF. The driving force or temperature difference between the chilled water and a room at 75ºF is therefore reduced, falling within the range of 15 to 20ºF as opposed to a conventional chilled water system using 40 to 45ºF chilled water and a range of 30 to 35ºF temperature difference.

Although radiant cooling and chilled beams reduce fan electrical energy demand and consumption up to 10 times from an all-air HVAC system, the pump energy demand increases, but this increase is miniscule in comparison to fan energy savings.

Of great interest to those looking to combat the COVID-19 pandemic via HVAC system design, chilled beams can be used to satisfy or surpass ASHRAE 62.1 requirements for ventilation air.

When the amount of outdoor air supplied to a space is increased, the volume of air circulated by the central system can be dramatically reduced in many situations. The net result is lower energy consumption and operating costs, along with a healthier indoor environment.

Of course, the implications of increasing fresh air to a building extend beyond COVID-19. All other airborne pathogens, allergens and indoor pollution are reduced.