By Justin Holland, Technical Sales Support Specialist for Heating Solutions Sales Company (HSSC), representing U.S. Boiler Company.

With the constant demand for improvements in comfort we provide to our customers, we need to strive to come up with solutions to accommodate our markets and keep up with our competition. The introduction of mainstream condensing boilers over twenty years ago opened new doors to how we can improve efficiency, lower utility bills and continue to revolutionize central heating applications. I want to discuss an important tool we can use to expand our opportunities for providing comfort as well as product efficiency and longevity.

One takeaway I have from my fifteen-plus years of residential heating and cooling is the desire over time of homeowners for more comfort control, whether it be with the improved technology of “Smart” thermostats to the desire of more individualized zoning. There were many times I remember customers wishing they could control the temperature of each bedroom in their home separately. While it sounded like a bit of overkill to me, it didn’t mean that it cannot or should not be done. In condensing boilers, smaller zones in homes can pose a problem for us with short cycling, even when we have modulation as great as the 10:1 turndown offered in our newer products. “Micro Zones” really are a thing: they can be the small sunroom zone, the master suite, the home office, or the partial finished basement; whatever the customer desires away from the usual living spaces.

Enter the buffer tank, which is an insulated “storage” tank, ranging between 10 and 120 gallons with a single chamber, vent, drain and multiple tappings: either two or four. In our application I would like to discuss four tapping tanks and how they benefit us.

In all our condensing boilers, the low water volume of the heat exchanger regularly requires primary/secondary piping. We often go into detail regarding the importance of closely spaced tees or use of a hydraulic separator between boiler loop and heating loop to emphasize correct piping practices. When we use a buffer tank, the tank acts as the hydraulic separator as well as a place to store excess heat. With those micro zones we discussed earlier, the excess heat that the zone cannot take is stored in the tank and prevents short cycling of the burner. For applications involving zones with different target temperatures such as a fan coil zone and a low temperature radiant loop, the tank’s stored heat can help to balance distribution to the low temperature zone before a burner call is necessary.

For example, let’s say we have a home with an Alpine 210 boiler. One of our zones might be smaller than the “main” zones, like a sunroom. The zone may require 10,000 btu, but the 5:1 turndown rate of the Alpine is higher than this zone’s load. If this zone calls for heat alone (and it does happen), the boiler’s cycle would be extremely short due to the lack of ability to expel the heat generated by the boiler. We should all understand that condensing boiler efficiency shines the most when its run cycle is longer, so for this example let’s use a minimum cycle of at least ten minutes. When the boiler spikes its target temperature quickly and satisfies prematurely, we not only create an inefficiency but also a reverse radiation: emitting heat from the heat exchanger out of the exhaust termination. This can also negatively affect many other boiler components due to unnecessary and excessive start/stop cycling. If a buffer tank is integrated into this heating system, the boiler would have the ability to run longer and maintain its lower modulation without short cycling the burner, all while providing equal comfort to the sunroom like it does to the larger zones in the home.

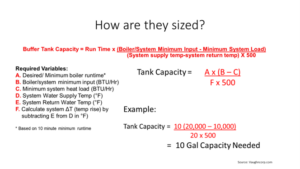

Buffer tanks are also used in other applications, such as apartment buildings with a central boiler or in certain commercial applications where zones could have drastic differences in heat load. Correctly sizing a buffer tank for your needs is important: if undersized you could still short cycle, while oversizing could cause unnecessarily long zone run time due to the tank absorbing more heat than the smallest zone requires. The formula for sizing a four tapping tank is as follows:

In this example, I used a 20-degree temperature differential (ΔT) as “F” for simplicity’s sake. Your system’s needs for ΔT may vary based on what you are heating (fin tube, cast iron, radiant, etc.).

Buffer tanks do have their place in our line of work. They aren’t needed for every zoning application but when the heating layout gets complicated or expansive, they can be very beneficial in not only providing the efficiency desired but also in equipment longevity. Those customers I spoke of from years back that desired individual room zoning could have their wishes accommodated by an informed heating contractor that plans their system layout by including a buffer tank. By having options like these in your back pocket, you as the contractor open yourself to more opportunities to provide your customers with new solutions as well as to generate revenue.