David Conigliari has been in the plumbing and heating trade since 1985. He’s watched northwestern New Jersey grow, and with it, the demand for premium comfort.

“Efficiency has always been a major determining factor when it comes to product selection and system design, but more and more, comfort is becoming as big a consideration,” said Conigliari. “There are a lot of affluent towns in this area with larger homes and particular customers that expect a high level of quality and service.”

He explained that hydronic heat is frequently requested, even on new construction projects. David founded his own company, Conigliari Plumbing and Heating, in 1993. Despite offering a wide variety of services, hydronic heating accounts for 70 percent of his work.

The company is based in Flanders, New Jersey, and work comes by way of referral, custom builders, and high-end architectural firms. Conigliari has opted to keep the company small. He usually employs one or two assistants. When big projects come along, which is not rare, David relies on a network of colleagues he’s formed over the years.

“Being the secretary of the Lakeland Chapter of the New Jersey State League of Master Plumbers puts me in contact with a lot of guys like myself, who are dedicated to trade and have small businesses,” said Conigliari. “We often help each other out when more manpower is needed. Many of these craftsmen have become great friends.”

Wow

Conigliari’s number one goal on every job is to “wow” the customer. He knows, if he can do that, he will always have more than enough work.

“My biggest challenge is making sure that I’m fair to the customer and to myself,” he said. “I won’t allow myself to deliver anything less than an excellent product. The customer needs to get what they’ve paid for – and in most cases, more – and I need to make a living. Both are of equal importance. If the scale tips one way or the other, my business would fail. Small businesses are more vulnerable to this than large ones, in my opinion.”

David wants his systems to impress customers aesthetically and through performance. The age of the building, size of the budget, and fuel source make no difference.

High performance oil

A referral in 2017 took Conigliari to a gated community in Kinnelon, NJ, where a 5,000 square-foot home was plagued with huge oil bills and a lack of sufficient domestic hot water. A 25-year-old sectional boiler with a tankless coil heated the five zones of fin-tube baseboard.

“We came highly recommended on this job, and I wanted to deliver,” said Conigliari. “The homeowner needed more domestic hot water, wanted to add a basement zone, and was hoping for smaller oil bills. Tall order.”

The solution included a 189 MBH U.S. Boiler Company MPO-IQ. In addition to the 87% AFUE oil boiler, an 80-gallon indirect-fired water heater was installed. Finally, a fin-tube zone was installed in the basement.

Above: After hiring Conigliari to install a new MPO-IQ boiler, the homeowners saved $2,000 last heating season.

“I’ve put in about two dozen MPO-IQ boilers,” said Conigliari. “The three-pass heat exchanger design makes the unit very efficient, and I’m always amazed at how clean the combustion chamber is after a year of service. I also use the plug-and-play outdoor reset card every time.”

David’s son, Nick, helped wire the job and Mike Schnuriger, a long-time friend from the New Jersey State League of Master Plumbers, was on the job from beginning to end.

“I received a letter from the homeowner about a year after the job,” said Conigliari. “They had saved $2,000 on their fuel bill, they had plenty of hot water, and the home was very comfortable. That’s what I like to hear.”

Half the capacity

Even though much of Conigliari’s hydronic work involves oil-fired systems, gas conversions are also pretty common.

In October, he was called to a lakefront home with a 50-year-old oil furnace and boiler, for a total of 300,000 BTUs. The homeowners wanted to convert to a single, gas-fired heat source, needed enough hot water for daily use of a large soaking tub, and also wanted to heat the garage.

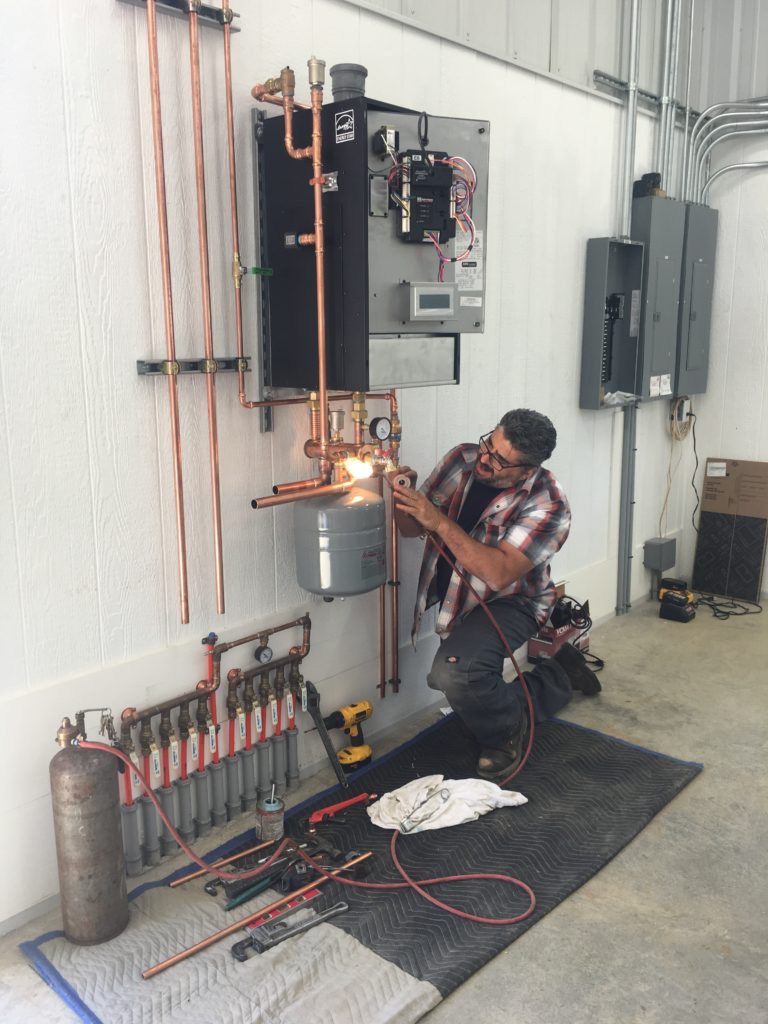

“It was pretty involved, and I wanted to nail down the design early,” said Conigliari. “I often call on manufacturer’s rep Venco Sales for help with projects like this. For years, Tom Dwyer and Jim Finan have been extremely helpful in the design process.”

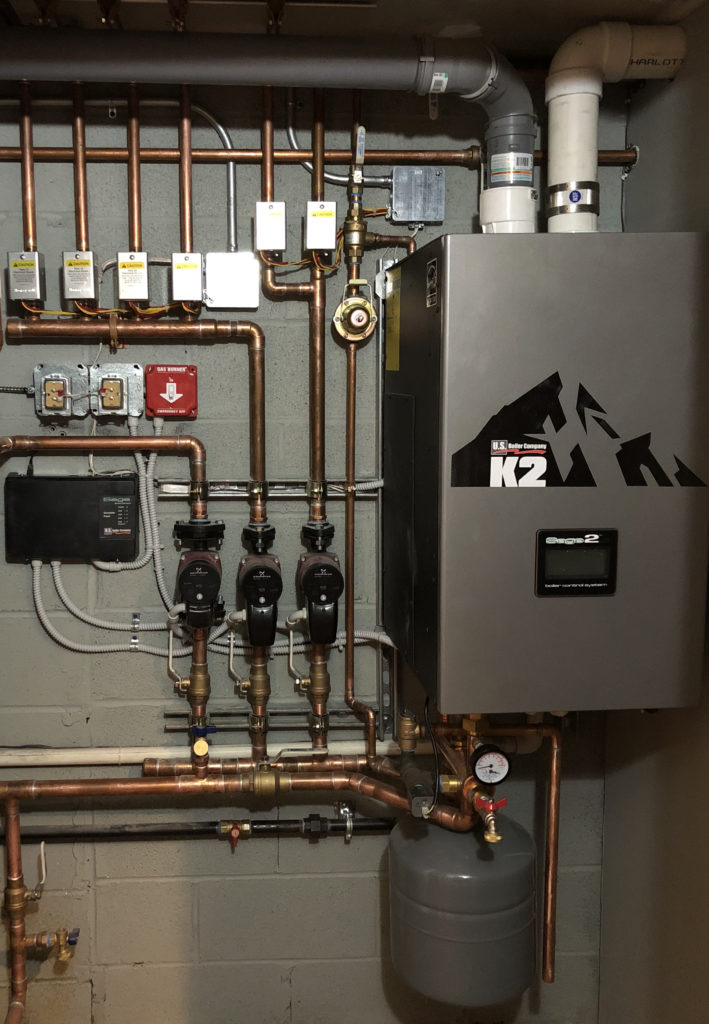

When the homeowners left for Hawaii, Conigliari hit the ground running. The existing oil-fired units were removed, as was the oil tank. David worked in a cold house for the majority of the two-week project. He ran a gas line, installed poly venting, hung a hydronic unit heater in the garage, piped a large sidearm tank and put a hot water coil in the home’s existing ductwork. Everything ties into a 150 MBH U.S. Boiler Company K2 high efficiency condensing boiler.

Above: Conigliari installed a 150 MBH K2 condensing boiler in place of the home’s existing oil boiler and oil furnace.

“The home now has literally half the BTUs it used to, and that’s with the system being designed for performance, not efficiency,” he said. “According to the heat load calculation, I could have managed with a 120 MBH boiler, but the owners wanted extremely fast DHW generation.”

When the owners came home from vacation, they found that the existing boiler room was completely vacant, ready to be used as storage. Conigliari was able to shoehorn the K2 boiler and indirect into a small basement closet.

No room for improvement

“I’m never the cheapest contractor to bid a project, but I sell jobs because people trust me based on referrals,” said Conigliari. “My goal is to build something as well as it possibly can be. That’s part of the reason I use U.S. Boiler products.”

Above: The K2 high-efficiency boiler is Conigliari’s go-to condensing boiler because of its features and the support he receives from Venco Sales.

Switching to the K2 boiler from his previous condensing brand was due almost entirely to the support Conigliari receives.

“I like everything about the K2,” said Conigliari. “It’s installer friendly, it’s efficient and it offers great value. But the real reason I switched condensing lines is because of the support that Venco Sales gives me. They made it an easy decision.”

With help from Venco on design, product selection, and start-up if needed, David’s confidence in taking on larger, more complex projects has grown in recent years. From steam boiler replacements to custom architectural projects, the small but capable company will continue building the best boiler systems possible.