By Candace Roulo

When reviewing the history of plumbing, it’s impressive to see how pipes and plumbing systems have evolved throughout the times. But what would the Romans – known for using lead pipes to improve sanitary conditions and developing aqueducts, underground sewer systems, public and private baths and lead and bronze water piping systems – and the Egyptians – known for making copper pipes to build bathrooms, irrigation and sewages systems – think about utilizing additive manufacturing (3D printing) to make plumbing and hydronic products? It depends on how advanced the Roman or Egyptian you are asking is.

These ancient civilizations were noted as having some of the most innovative and progressive people ever, so let’s assume the Romans and Egyptians we’re asking are advanced individuals, constantly pushing boundaries.

First of all, these Romans and Egyptians would be pleased with all the advancements, noted on theplumber.com, made up to this year. They would be pleased with King Louis XIV ordering construction of a cast-iron main plumbing line to carry water from a pumping station to the palace fountains (1664).

They would be in awe of the advancements in New York City – an underground sewer was installed in 1728 and in 1830 the first public water main was installed under New York streets. By the time 1845 rolled around, they would find it fitting that drainage piping systems were installed in buildings, helping convey sewage away from these structures. They would celebrate the passing of The National Public Health Act in 1848 and the first plumbing code, nicknamed the Hoover Code, published in 1928.

Then there is the birth of the PVC pipe in central Germany. From 1936 to 1939, more than 400 residences were installed with PVC drinking water and waste pipelines in central Germany. But it wasn’t until 1950 that the systematic development of extrusion technology started. Before this time, the use of PVC pipes was not common. Starting in 1966 and due to a shortage of copper, non-metallic pipe (PVC) became part of modern plumbing systems, and now you can find PVC pipe everywhere. Chances are, our Roman and Egyptian friends would be quite impressed with this plastic pipe.

3D Printing Hits The PHVAC Industry

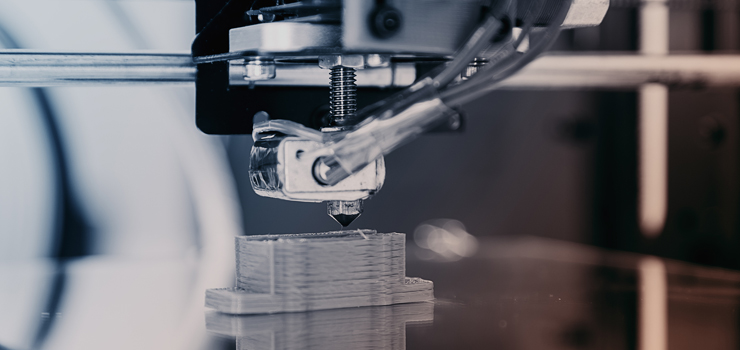

But what would really knock our ancient friends’ sandals off is additive manufacturing, also known as 3D printing! 3D printing is a process of making three dimensional solid objects from a digital file. 3D printed objects are created using an additive processes in which an object is created by laying down successive layers of material until the object is created, according to 3D Printing.com. Each layer can be seen as a thinly sliced horizontal cross-section of the object. With 3D printing it’s possible to make complex and functional shapes using less material than traditional manufacturing methods.

By now, I’m sure you’ve all seen 3D printed plumbing fixtures, such as the Grid Sink faucet by Kallista and the Vibrato Bathroom 3D faucet from DXV by American Standard (our Greek and Egyptian friends would love the design of these high-end faucets).

Besides producing these eye catching, in-front-of-the-wall products, 3D printing is useful for some in-back-of-the-wall products, too. According to 3DPrinting.com, 3D printers can be used to create pipe connectors and threaded caps. But 3D printing’s real niche in the PHVAC industry is not to create common pipes and pipe fittings, but to create custom and hard to source parts – many that are no longer on the market – such as new handles for the Hoffman No. 7 steam radiator valve or Warren Webster type W valve handles.

Below, watch Hoffman No. 7 steam radiator valve handles being produced with a 3D printer.

According to a PHVAC business owner, who is also a contractor, the ability to 3D print hard to source parts – like old faucet stems – for the plumbing side of the business would be of value and the possibilities of 3D printing would seem endless. But our ancient Roman and Egyptian friends might wonder how manufacturers will protect proprietary patented information and where does this leave wholesalers and distributors.

The PHVAC business owner doesn’t know how manufacturers would like to reveal detailed proprietary patented information while losing the revenue otherwise gained in the sale of those parts, but believes that in the future, a monetary exchange will take place to have the patented information directly inputted into contractors’ 3D printers with a limited number of uses.

The ancient Romans and Egyptians want wholesalers to keep abreast of this technology. According to the article “Additive Manufacturing – Wholesale Distribution Trends #12” by Paul St. Germain, distributors must keep an eye on this technology as it advances and consider its application to their business.

“For example, they should consider its applicability to service parts and repairs, especially for slow-moving inventory items, particularly in the automotive, aerospace and marine sectors. At some point, it may become feasible and more practical to print out replacement parts rather than buying and stocking them,” writes St. Germain.

Even though St. Germain writes about automotive, aerospace and marine distributors, wholesalers and distributors in the PHVAC industry need to take his advice and think about how 3D printing may affect the future of their specific industry and how they can evolve their businesses.

The construction industry may not be moving ahead with this technology as quickly as other industries, but there is definitely a place for 3D printing in the PHVAC industry. Our Roman and Egyptian friends visiting us in 2019 believe it’s only a matter of time before 3D printing disrupts the construction and PHVAC industry. Wholesalers and distributors need to stay on their toes, keep up with the technology, and evolve with it.

Candace Roulo, a graduate of Michigan State University’s College of Communication Arts and Sciences, is a technical writer covering topics in the mechanical contracting and manufacturing industries.