Super Bowl LIII is almost upon us! Before too much longer, we’ll watch the New England Patriots battle the Los Angeles Rams. As you slip into your recliner to watch the last game, you might complete a mental rundown of your Fantasy roster and what you wished you had done differently. Perhaps the thought of getting a bigger TV crossed your mind.

But what you never stopped to ponder, more than likely, is the field itself; the actual playing surface. Of the 31 NFL stadiums in the country, only a handful still feature real grass. That number is dwindling as synthetic turf technology progresses. Safety is the primary concern, more so than expense. After all, Carson Wentz’s torn ACL or Tom Brady’s meniscus is worth far more than the cost to resurface a football field.

Gillette Stadium featured real grass until one particularly muddy game against the Jets convinced club management to switch to synthetic turf. But, it’s worth looking more closely at Gillette’s previous playing surface. While the NFL keeps trending away from real grass as players get bigger and faster, other sports still have a keen fondness of a surface that needs to be mowed. Soccer and baseball are at the top of the turf-loving list. And if a winter game can be played on real turf in Massachusetts, it can be done just about anywhere.

Radiant Grass Growth

So how did the grass grow through a New England winter? The same way you heat a house or clear a snow-covered driveway with tubing and hot water. Before it was replaced with synthetic turf, the field in Gillette Stadium covered a high-dollar heating system that included more than 150,000 lineal feet of PEX tubing. A turf warming, or turf conditioning system is similar to a snowmelt system, but there are key differences that separate them.

Above: The average heated sports field utilizes between 20 and 30 miles of radiant tubing.

“The main difference is what our objective is,” says Watts Radiant engineer Kolyn Marshall, system engineering manager at Watts who designed the system for Gillette Stadium. “In a snowmelt system, we’re trying to melt snow at the surface. To do this, we need a surface temperature greater than 32°F. In a turf system, our target isn’t the surface, but rather an area 6”-10″ down where the root zone is. This layer is designed to maintain anywhere between 50-60°F, depending on the turf, soil conditions and climatic conditions.”

There are times when a turf system will melt snow, though it’s really not designed to do this. The system’s sole purpose is to keep the turf growing all winter. A football game inflicts damage to a live playing field, and the grass needs to recuperate.

Of the sports played professionally in the United States, gridiron football is almost unquestionably the most aggressive in terms of playing surface abuse. Sure, soccer and baseball demand high levels of athleticism, but the play is spread out across the field, and lighter in overall traffic. It’s hard to match the damage inflicted to the turf when 300-pound, cleat-footed linemen are doing their best to plow through each other. Especially when that wear and tear is concentrated at the center of the field, down, after down, after down.

While heated grass fields – and natural turf in general – are losing favor among NFL franchises, they’ve piqued interest in other arenas. After all, 28 of the 30 MLB fields still feature natural grass, and pro soccer is booming in the United States.

New York Red Bulls

The New York Red Bulls professional soccer team recently built a new facility not far from Newark, NJ. It includes three playing fields, the largest of which is radiantly heated for use in winter. LandTek Group, Inc., a large sports field contractor based in Amityville, NY, won the bid.

The heated field is sized at eight million BTUs. Flow rate and supply temperature are controlled through the use of outdoor reset and soil temperature sensors. The temperature of the water/glycol mix is usually between 85 and 120°F. So far, it doesn’t sound that much different than a radiant system right?

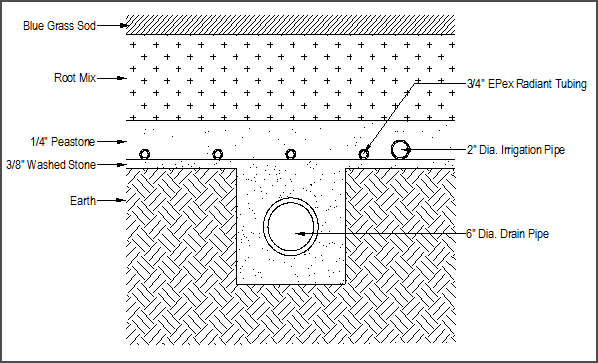

Above: With a heated turf field, grass covers at least 4 layers of substrate and 3 piping systems.

Well, there are at least five different layers to a turf field, and an extensive drainage and irrigation systems as well. It starts with hard-packed earth, then layers of progressively smaller stone, and sometimes sand. This aggregate is followed by a specially engineered soil, or “root mix”, on which the turf grows, most often Kentucky Bluegrass or some Fescue variety.

Above: The radiant tubing is placed on top of the base stone layer. It’s held in place by a rail system that’s spiked into the stone, ensuring proper spacing. The heat must penetrate about 10 inches of sand and peastone before it reaches the grass root zone.

Why So Deep?

Aeration of the soil is a key consideration. Different fields require different aeration techniques, but one thing is the same: something must penetrate the field in the aeration process. The radiant tubing and irrigation equipment needs to be deep enough to avoid damage. Plus, the thicker substrate, the less likelihood of an injury when a player falls.

The 135,000 lineal feet (or 25 miles) of PEX at the Red Bull field is laid out in a reverse-return format to achieve self-balancing and to reduce head pressure. ‘Thermal striping,’ or inconsistent temperature across the field, would be an issue if not for the fact that tubing was laid on relatively tight centers.

A huge, 360-foot-long polyethylene manifold set was fabricated on-site by heat-fusing 20-foot sections together. Each loop is 520 feet long, and the field is one giant zone. Once the system was up and running, and the new sod was rolled out, the soccer club gave the grass a few months to establish itself before using the field.

Above: The 360-foot manifold set was formed onsite by fusing together 20-foot pre-manufactured sections.

Regardless of the sport played, a turf conditioning system results in a healthy grass playing surface that’s better cushioned, causes fewer skin abrasions and more serious injuries, and plays well.

Game on!